Plate and Shell Heat Exchanger is designed as a performance upgrade over shell & tube heat exchanger and welded, brazed plate heat exchangers. This heat exchanger type supplies high thermal performance with compact size, similar to that of gasketed plate heat exchangers, with low hold-up volume and low installed weight, especially when filled. But it can be applied well when the operation condition is high temp and high pressure to which gasketed plate heat exchangers cannot be applied.

BOGE plate and shell heat exchangers combine the strengths of both shell and tube heat exchangers and plate heat exchangers, retaining the high working pressure and temperatures of the former coupled with the high efficiency of the latter. A “best of both worlds” solution, our plate and shell heat exchangers provide unmatched performance for a wide range of applications, particularly vapor condensation duties.

The heart of the Plate and Shell Heat Exchanger is its heat transfer element, also called the plate core/package, composed of round or oblong chevron-type plates welded into a cassette.

Features and benefits

Very adaptable heat exchanger. An excellent choice for handling condensation duties, especially duties without condensate sub-cooling. They are also perfect steam heaters of clean fluids, demineralized water, and clean thermal oils.

The heat exchanger is designed to be highly resistant to thermal shocks as well as thermal and pressure fatigue making it very well-suited for cyclic duties and other duties with sudden, large fluctuations in temperature.

Available in both bolted and fully welded designs. The fully welded types can handle higher temperatures and pressure levels than the bolted types but cannot be opened for cleaning. This can instead be done with CIP (Cleaning in Place) systems.

What are the advantages of Plate and Shell Heat Exchanger?

High heat transfer & Low fouling

Compact structure & No gasket

High pressure & High temperature

Small terminal temperature difference & Low pressure drop

Applications

HVAC industry

Marine/offshore industry

Dairy/food/beverage industry

Sugar industry

Biogas industry

Refrigeration industry

Pulp and paper industry

Heavy industry

Mining industry

Petrochemical industry

Chemical industry

Condensation

Steam heating

Oil coolers

Gas heaters/coolers

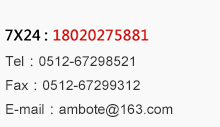

180 2027 5881

180 2027 5881