BOGE plate type condensers are specifically designed for condensing of vapour under vacuum. These plate surface condensers are ideal for use in applications such as vacuum condensers in evaporation systems, ethanol condensers in bioethanol plants, pan vapour condensers in sugar refineries, and as turbine condensers in small power plants. With its compact design,Plate type condenser is easy to install where space is crucial.

Highly efficient and very compact

In order to achieve the best condensation effect, our wrench condenser’s plate channel is designed as a wide channel and a narrow channel, with a large channel on the steam side, so that the pressure drop on the steam side becomes very low, and the cooling medium The side has a narrower passage, but still maintains a certain flow rate to achieve turbulence. Therefore, such design makes it with higher heat exchange efficiency and lower fouling coefficient.

Recommended Applications

The plate condenser is primarily used in conjunction with a plate evaporator as a condensation of steam in an evaporation or distillation system. For example, the condensation of steam in the syrup 3-effect evaporation system, the condensation of steam in the juice 3-effect evaporation system, and the condensation of steam in the multi-effect evaporation system of the ethanol concentration in the ethanol industry, and the like. The plate condenser is used in more and more condensation occasions due to its high heat exchange effect, low input cost and convenient maintenance operation.

What are the advantages of plate condenser?

Porthole configuration design specially for maximizing heat transfer processing

Different channel gap sizes of two side media for minimizing fouling

Compact welded structure for lowering equipment cost

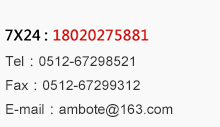

180 2027 5881

180 2027 5881