EATING AND DRINKING ARE PART OF OUR LIFE – AND OF OUR ENJOYMENT

More and more people are able and willing to purchase not only fresh food, but also food and beverage products that have been processed reliably and with superior quality.

Both of these expectations place the strictest of demands on food-processing technology: after all, optimal standards in cooling, shelf life, and in process cleaning, disinfection, and drying are absolutely critical for fulfilling these requirements in worldwide production. At the same time, companies in the food and beverage industry are engaged in global competition and are responsible for finding sustainable solutions in their work. As a result, efforts performed to ensure quality, efficiency, and reliability must smoothly interact.

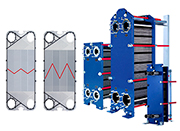

From one source, we offer you plate heat exchangers for the food and beverage industry – ranging from highly standardized solutions all the way to individual implementation. Wherever heating or cooling are involved, you will find an integrated solution from us – one that will take into account not only your interests, but also those of your customers. We are your reliable partners throughout the entire value-added process chain.

Application of Plate Heat Exchanger in Beer Production

Beer has become an indispensable part of mass consumption. Beer production process mainly includes malt preparation, malt juice manufacturing, fermentation, filtration sterilization, filling and packaging. After filtration, the malt is processed by the boiling mash kettle and then the malt juice is obtained. The wort needs to be cooled by the plate heat exchanger to the fermentation inoculation temperature before fermentation then can be carried out to achieve higher fermentation efficiency. After the fermentation, the draft beer is obtained, and the draft beer is cooled down to a suitable storage temperature by a plate heat exchanger and then other treatments are carried out.

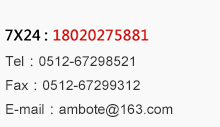

180 2027 5881

180 2027 5881